Infra-Red (“IR”) Technology

Infra-Red Drying technology has been used as a drying technology for decades. Prime’s Premier Controller increases both the energy efficiency and effectiveness of this proven drying technology.

Infrared drying is an indirect heating method that can be used to dry and/or heat a variety of substrates and materials. Since Infra-Red drying is a line-of-sight drying technology, it does not rely on an intermediate fluid such as air or water. This helps make Infra-Red drying technology a very energy-efficient drying and/or heating technology that can be effectively and efficiently used for a wide variety of printing, packaging, converting and industrial applications. During the IR process thermal radiation energy (radiation typically between 0,78 µm, and 1000 µm on the electromagnetic spectrum) from an IR element is transferred from the IR element to the substrate or materials.

Infrared Energy is typically classified into 3 principal segments. These are as follows:

Short-wave IR: 0,77 µm to 2µm range

Medium-wave IR: 02 µm to 4µm range

Long-wave IR: 4 µm to 975µm range

The benefits of Short-wave IR radiation include emitting a relatively high-power density in a small area. In addition, these IR emitters come to operational temperature in a quick time period and cool rapidly as well. For these reasons, Short-wave IR is often used where deformation of the substrate can occur in a short time period.

Other advantages of IR drying technology include the following:

Relative to hot-air and gas dryers, IR drying is compact requiring much less space.

Prime IR dryer design allows for IR segments to be turned on and off to closely match the substrate / material size thus reducing energy consumption.

IR emitter power drivers are programmable to increase and decrease power output as a function for process speed further increasing energy efficiency.

As a line-of-sight drying technology direct contact with the substrate/ material is not required.

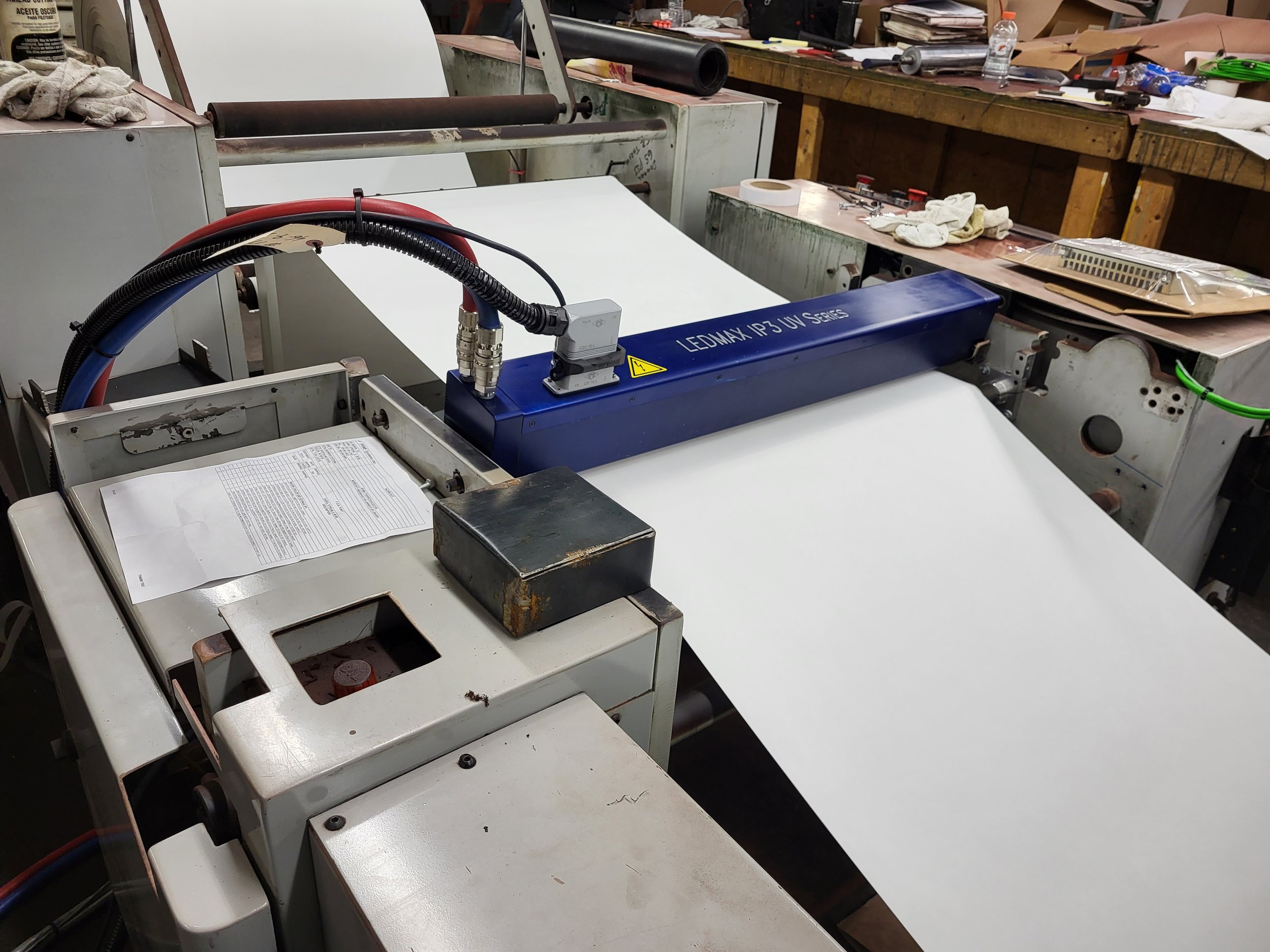

Prime’s IR CASSETTE Technology:

Prime’s IR Emitters are manufactured using the finest quartz available to ensure durability, reliability and longevity. Prime’s IR Cassette design allows the use of either Prime’s Short Wave, Fast Medium Wave or Medium Wave IR Emitters. Providing these options enables the IR Cassette to emit IR Energy best matched to the absorption spectrum of both chemistries and substrates used to optimize drying efficiencies. Providing maintenance ease, Prime’s IR Cassette simply slides in & out to allow fast and easy access for any servicing.

The IR Emitter Zone allows adjustments of the IR Cassette’s distance to the substrate to best accommodate material thickness variations. All of Prime’s IR Emitter’s come with Gold Reflectors which reflect more than 90% of IR output to the substrate. Further reducing energy consumption, Prime’s IR cassettes are powered by Prime’s PREMIER Controls. Controls that enable IR section activation to best match substrate width variations and automatic 1% power output changes to best match process speed.

Prime’s IR Zone ensures the highest radiation efficiency with minimum convection loss. The IR Zone includes a series of fans directing heat towards the substrate. This IR Zone delivers maximum radiation power in minimal space.

Recommended prime products for this TECHNOLOGY

Get in Touch with a Product and Application Specialist

Contact us to learn how Prime UV-IR’s curing and drying solutions can improve your production process, reduce your energy consumption and expand your product offerings.