UV LAMP CURING SYSTEMS

In use for over fifty years, UV Lamp Curing Systems remain very effective and energy efficient for numerous applications and are the most compatible UV systems to use with certain UV Chemistry.

Over fifty years ago UV lamp systems were designed to cure (dry) newly developed UV Chemistry. UV Chemistry was found to have 3 main benefits: 1) Immediate Cure 2) Energy Efficient 3) Reduced equipment footprint (less space.)

At that time, UV systems all employed both water cooling and air cooling to properly cool the vital components of the UV system: the UV bulb and the UV reflectors.

Since that time all aspects involved in the UV printing process have improved dramatically. These include the UV auxiliary supplies such as UV chemistry, UV cleaning solutions, UV plate, blankets and, of course, UV equipment.

Years ago high speed UV printing occurred at 300 fpm (100mpm.) Today high-speed UV printing occurs at 2400fpm (800mpm.)

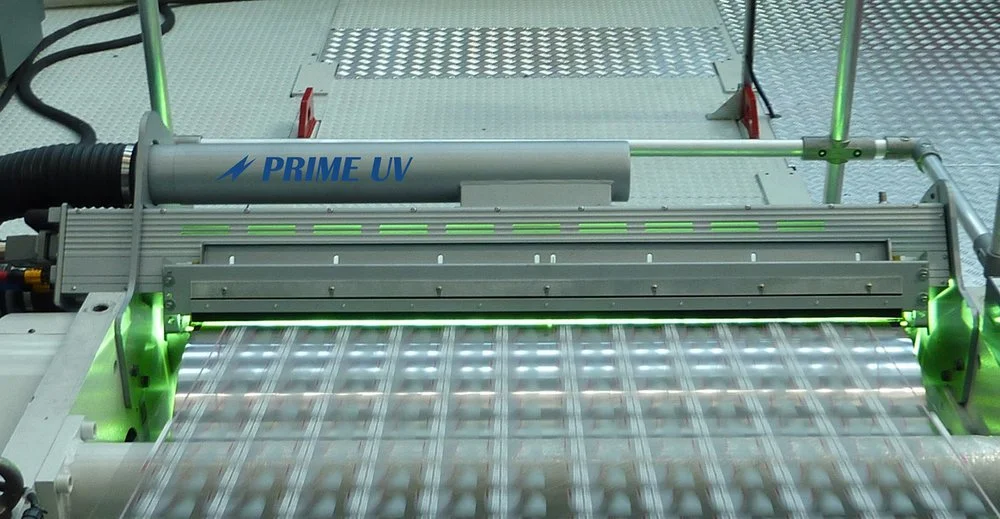

Today hundreds of UV equipment manufacturers exist worldwide. However, less than 6 UV equipment manufactures exist in the world who design and manufacture UV equipment that is dependable to operate 24/7 in high-speed, wide substrate applications. Prime UV-IR Systems in one of these rare UV manufacturers.

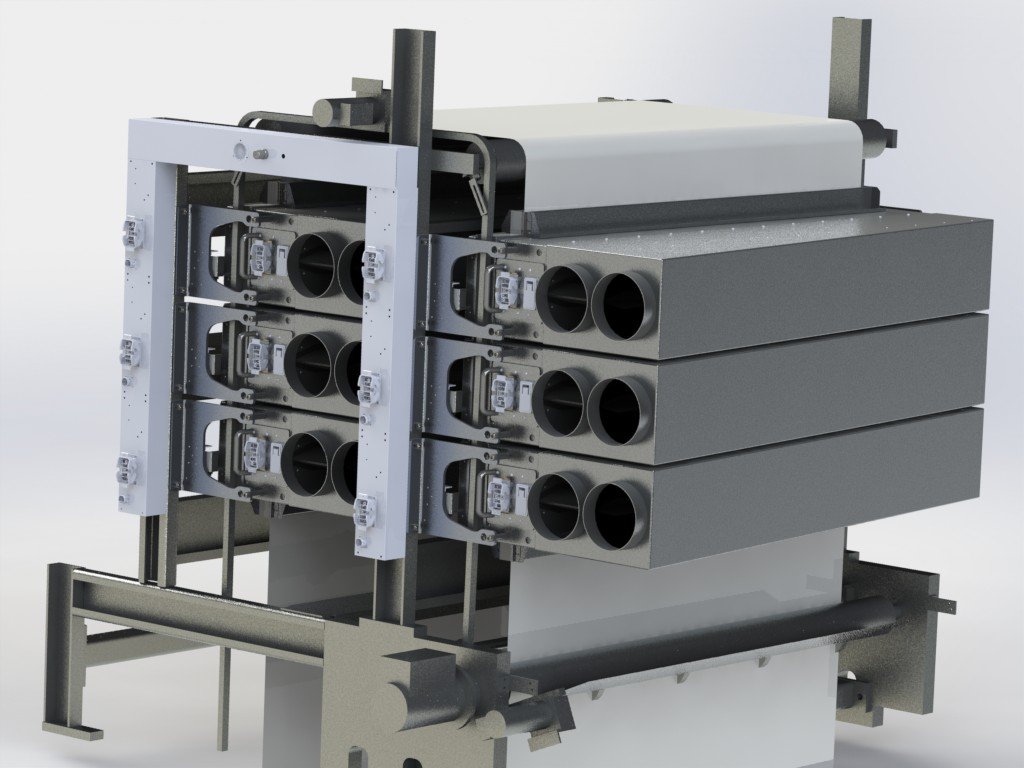

With so many UV manufacturers there are a number of ways in which to design and build a UV system. However, for the most part, the common main assemblies which exist in a UV system are the following: UV bulb, UV reflector(s), UV power driver / ballast, air blower and / or water chiller, PLC controller and HMI.

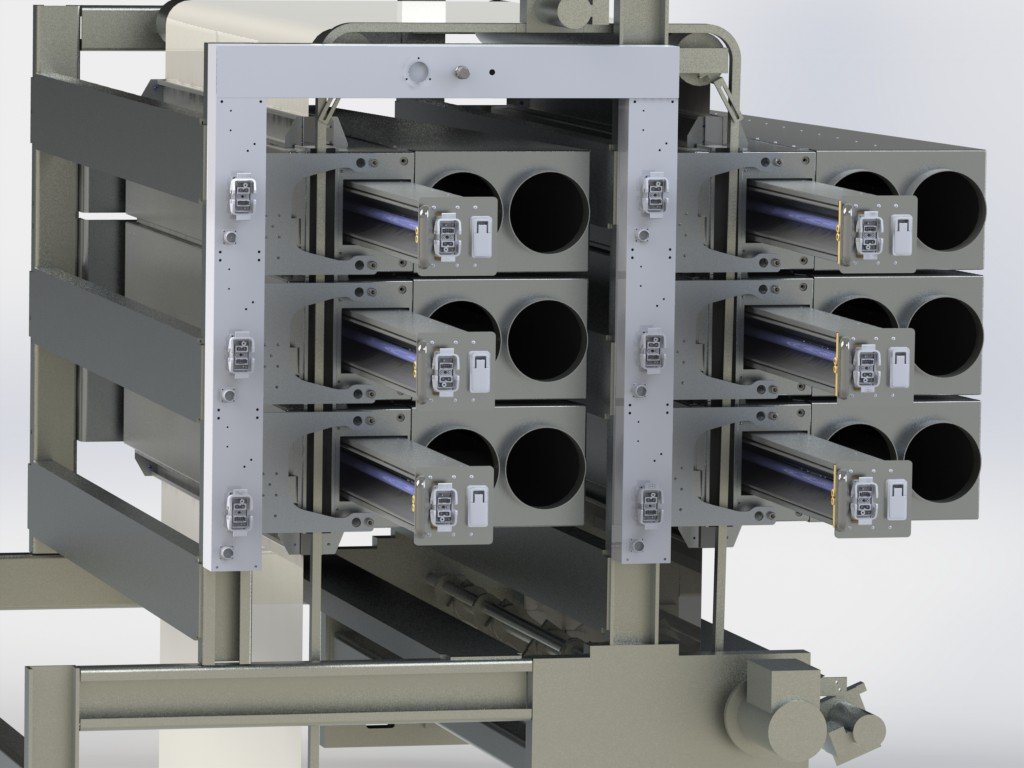

The UV bulb and the UV reflector(s) are often part of a main assembly called the UV inner cassette. The UV Inner Cassette is then part of a larger assembly called the UV Outer Housing. The UV outer housing shields operators from the UV energy, IR energy and light which is emitted from the UV bulb. The outer housing also guides air (water as well in certain UV systems) through the inner cassette to ensure that the UV bulb and UV reflectors are kept at the proper operating temperatures.

UV Bulb

The heart of the UV curing system is the UV bulb - a 3⁄4” (common size) diameter tube of quartz glass with gold and ceramic ends that attach to high voltage wire. Elliptical reflectors with highly polished reflector liners encompass seventy five percent of the UV bulb and concentrate the UV light on the printed web ensuring fastest printing speed.

UV Shutters

Since some UV bulbs emit UV energy up to 800 watts per inch, the UV inner cassettes typically include automatically controlled shutter(s) that close in front of the UV bulb when the substrate stops. Often this UV shutter is computer controlled and protects the substrate during process stoppage. The UV shutter then opens instantly when the substrate starts to move and ensures that all printing of product will cure.

Prime UV incorporates light shields on the UV Outer Housing that vary in design to best suit both the application and UV processing units. Light shields are designed to eliminate exposure of direct UV light and minimize reflected UV light to the operator and plant personnel. To ensure light shields are performing there intended purpose, plant personnel should check light shields daily when the equipment is in the off position.

Prime UV Inner Cassettes include a highly focused elliptical shutter reflector system which maximizes UV Peak Irradiance and concentrates the UV bulb energy on a narrow band across the substrate. This high impact UV energy activates the UV ink photo-initiators to its maximum speed.

For over three decades Prime UV- IR has been engineering and manufacturing high performance UV Curing Systems which specialize in controlling, maximizing and optimizing the UV energy being delivered to the substrate.

The following UV terms are important to learn and understand when comparing UV systems, whether they are UV Lamp systems or UV LED Systems. These terms are also important when analyzing the performance of UV Chemistry.

UV Irradiance is the radiant power, within a stated wavelength range, arriving at a surface per unit area. It is photon flux, and is expressed in Watts or milliwatts per square centimeter. Irradiance varies with lamp output power, efficiency and focus of its reflector system, and distance to the surface. (It is a characteristic of the lamp geometry and power, so it does not vary with speed).

The intense, peak of focused power directly under a lamp is referred to as “peak irradiance.” Irradiance incorporates all of the individual effects of electrical power, efficiency, radiant output, reflectance, focus, bulb size, and lamp geometry.

UV Dose is the radiant energy, within a stated wavelength range, arriving at a surface per unit area. It is the total accumulated photon quantity arriving at a surface. Dose is inversely proportional to speed under any given light source, and proportional to the number of exposures (for example, rows of lamps). Dose is the time-integral of irradiance to which a surface is exposed as it travels past a lamp or a sequence of lamps. Dose is expressed in Joules or milliJoules per square centimeter. (No information regarding irradiance, irradiance profile, or peak is conveyed in measurement of “dose”.

Spectral Distribution is the relative radiant energy as a function of wavelength or wavelength range. It is the wavelength distribution of radiant energy emitted by a source or arriving at a surface. It may be expressed in power units or in relative (normalized) terms.

Analyzing the radiant energy from a bulb by grouping spectral energy into 10- nanometer bands yields a distribution plot (or table), which is more convenient to apply to spectral power and energy calculations than fine-resolution data.

Infrared Radiance: The amount of infrared energy emitted by the quartz envelope of the UV source. The heating effect it produces may be a benefit or a nuisance.

SIGNIFICANCE OF UV IRRADIANCE

All inks, coatings, or adhesives will absorb the UV arriving at the surface, but the radiant power available deeper within the ink/coating film will depend on the absorption in the ink/coating film. The higher the radiant power at the surface, the higher the power at any depth within the material.

The reduction of light energy as it passes into or through any material is described by the Beer- Lambert law. Energy, which is not absorbed in an upper layer of the film and not reflected, is transmitted and available to lower layers, according to the following expression.

Iαλ = Iολ (1-10-Αλ) d

Ιο is the incident energy at wavelength λ, Ια is the energy absorbed, Αλ is absorbance at wavelength λ, and d is the depth form the surface or film thickness.

DOSE-RESPONSIVE VS PEAK RESPONSIVE MATERIALS

“Dose” is the most-often reported measure of UV exposure, but when referenced alone, without other information, it is an incomplete specification. Dose is included here as an important factor in process specification because it is the only one which includes time. In many cases, the only controllable variable in a curing process is speed (or time). In such instances, dose is the only variable, which can be changed.

Clear coatings and varnishes tend to be dose-responsive. In other words, increasing dose alone may increase their practical cure speed. Practically, increasing the number of exposures under second or successive lamps will increase cure speed proportionally. However, this is becoming an exception rather than the rule.

Recommended prime products for this TECHNOLOGY

Get in Touch with a Product and Application Specialist

Contact us to learn how Prime UV-IR’s curing and drying solutions can improve your production process, reduce your energy consumption and expand your product offerings.