Paper Packaging UV-IR Business Applications

Paper can be used in flexible packaging, in boxes and in corrugated containers. Paper can also be printed or coated on sheet-fed or web processing lines. Printers may apply ink, coating, or adhesives through a variety of print processes such as Flexo, Offset, Gravure, or Digital. Due to the vast array of paper types, in-line UV curing systems or Infra-Red - Air impingement drying systems often prove very beneficial to help printers and converters deliver a higher quality printed and/or coated product in a much shorter time period.

Advantages of UV on Paper Packaging:

Ability to run Roll-to-Roll or Roll-to-Sheet

UV Chemistry has no VOC's

Capability to run on both Coated and Uncoated Stocks

Faster Press Speeds

Instant curing (drying)

Reduced Processing Times

Advantages of IR & AI on Paper Packaging:

Ability to run Roll-to-Roll or Roll-to-Sheet

Water based Chemistry has reduced VOC's

Capability to run on both Coated and Uncoated Stocks

Faster Press Speeds

Certain water-based chemistry approved for direct food contact.

Reduced Processing Times

Recommended prime products for this application

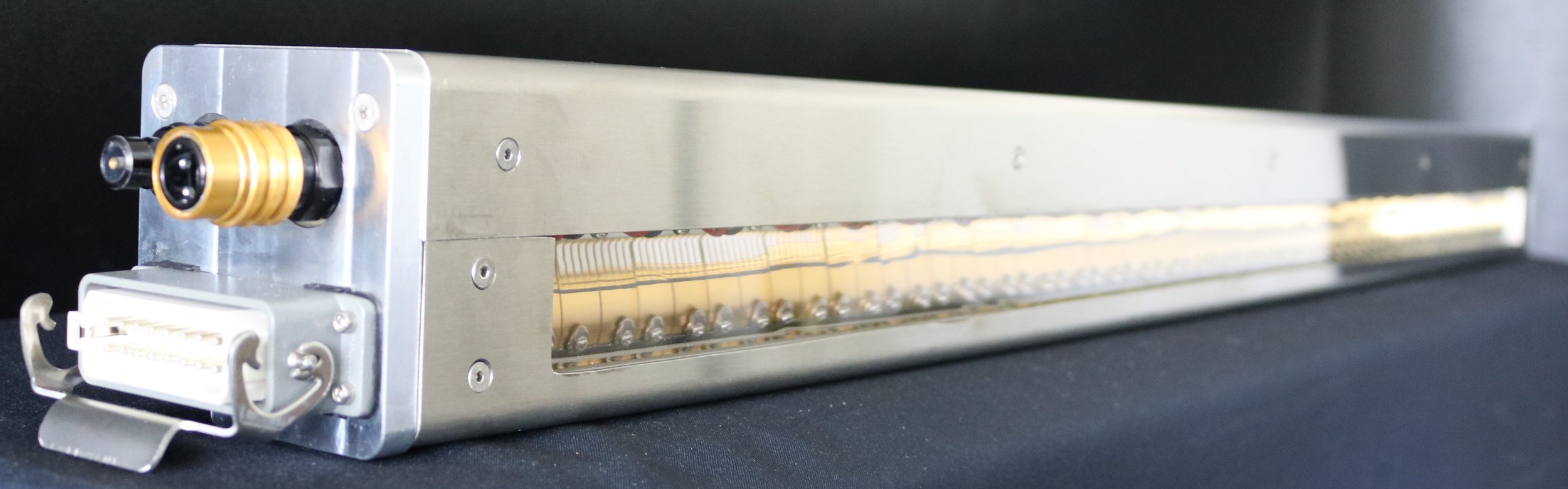

optimum

radmax

LEDMAX IP2 Water Cooled

LEDMAX IP3 Water Cooled

LEDMAX IP4 Air Cooled

Minimax

nitro uv

IR-AK6 HYBRID

Get in Touch with a Product and Application Specialist

Contact us to learn how Prime UV-IR’s curing and drying solutions can improve your production process, reduce your energy consumption and expand your product offerings.