Flexographic Printing UV Business Applications

Flexography is a modern high-speed printing process suitable for many packaging and label applications. It allows for fast, cost-efficient, high-quality label printing for a variety of mass-produced goods.

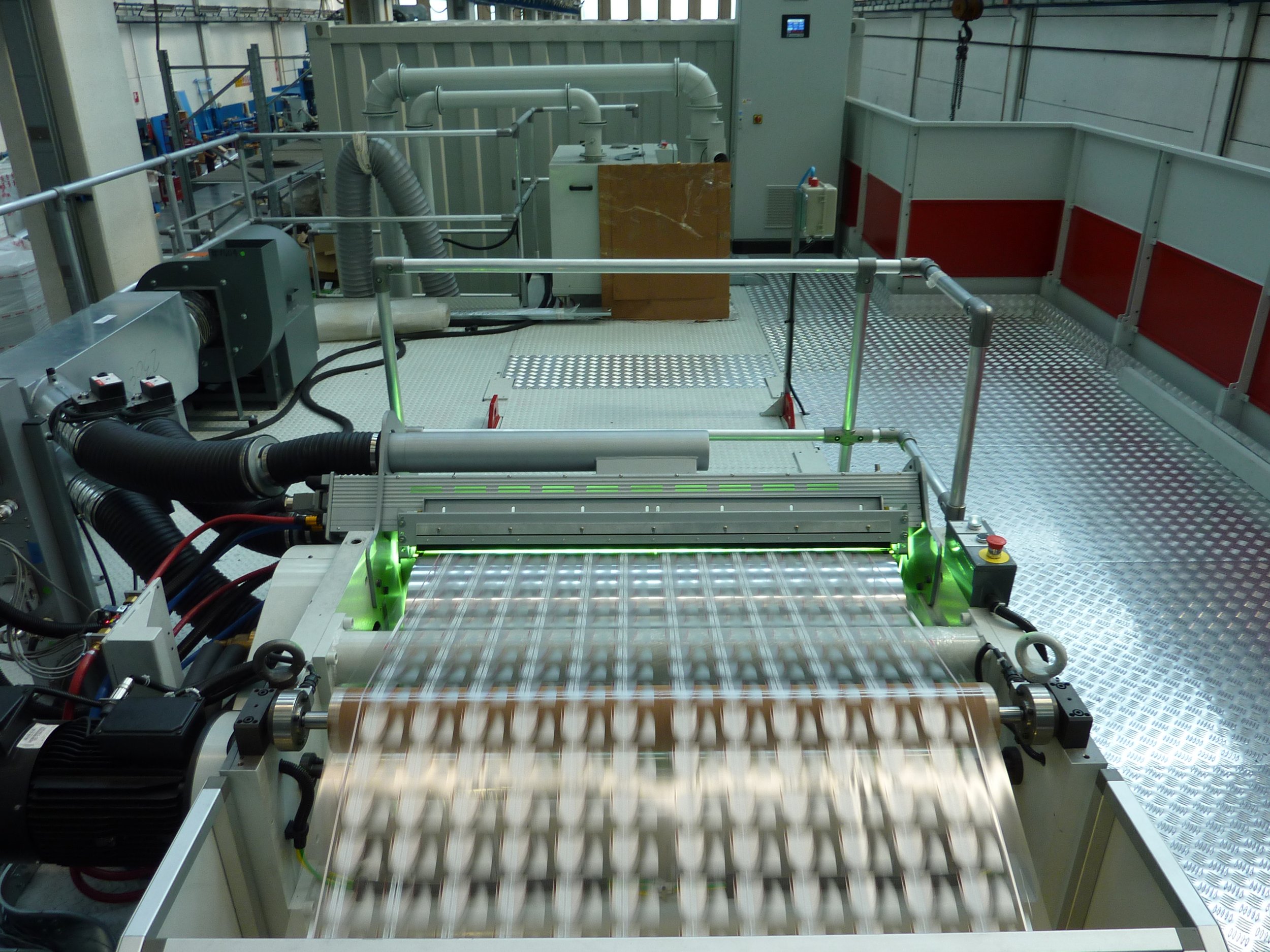

In flexographic printing, the starting material comes in the form of a roll, which passes through a series of rotary flexible relief plates. A specialized roller feeds each flexible plate with ink, with a single flexible plate required for each individual printed color. The relief plates work in tandem to provide all colors for the final print product.

In cases where additional processes are required – such as laminating, embossing or die-cutting – they can be integrated along with printing in a single pass, greatly increasing production speed and capabilities over more traditional printing methods.

Flexographic printing also allows for printing on various substrates, including paper, plastic film, corrugated cardboard, non-woven fabrics, metallic surfaces and multilayered film composites. This flexibility in substrates has led to the use of flexographic printing to print and convert a wide range of products such as self-adhesive labels, cut & stack labels, food packaging, multi-wall bags, and shrink wrap,

Today flexographic printing machines offer efficiency and speed advantages over many other label printing methods. Flexographic presses can print label rolls of various materials quickly with only a minor sacrifice in quality when compared to offset and gravure printing methods, making it the ideal printing method for many food, beverage, and consumer products.

UV FLEXOGRAPHY uses UV inks that cure(dry) when exposed to ultraviolet energy rather than the standard drying methods used for water, soy or solvent-based inks. UV inks cure(dry) instantly when exposed to UV energy which is much faster than the drying time required for other types of printing chemistry.

UV curable inks offer a wide range of production and sales advantages. These include the following:

Faster drying

Volatile organic compound (VOC) free

Superior print quality for many applications. Elimination of distorted printed dot.

Only dry when exposed to UV, so the printer can be left print-ready

Easy to use

Wide variety of substrate types including plastics, glass, metal, metalized films, flexible films, coated papers and mylar.

Get in Touch with a Product and Application Specialist

Contact us to learn how Prime UV-IR’s curing and drying solutions can improve your production process, reduce your energy consumption and expand your product offerings.