IR - HAK ACTION SHEETFED DRYERS

Prime’s IR-HAK ACTION Dryers provide the highest speed drying for years of operation in harsh operating environments. Prime’s IR Action Cassette simply slides in and out providing fast and easy access for servicing. Prime’s innovative HAK’s geometry guarantees a constant hot air stream to expedite the drying process and maximize drying speed. Prime’s design combines convection, IR Radiation and air-impingement drying technologies creating a superior, more energy-efficient dryer.

Prime’s IR-HAK design guarantees the highest delivered drying energy to the sheet.

Highest Speed IR -HAK drying of water-based inks, coatings, and adhesives available in the market.

IR Action Cassette & HAK3 construction is easily retrofittable in press delivery either upsweep or extended delivery section.

-

Gold reflector on top half of the bulb

Redirects IR short waves output to the substrate

-

Multiple reflectors

-

Directly focuses virtually 100% of IR beam to product

Increases intensity and peak efficiency

IR modules / surrounding equipment operate cooler

Guarantees energy is not wasted

-

Enable IR section activation to best match substrate width variations

Include automatic 1% power output changes to automatically adjust to best match process speed and substrate temperature.

Maximize IR Emitter life

VFD control of HAK – high-pressure air impingement technology to increase energy efficiency and optimize drying performance to best match ink coverage, substrate type and press speed.

Prime IR - HAK Action Dryer Energy Saving Features:

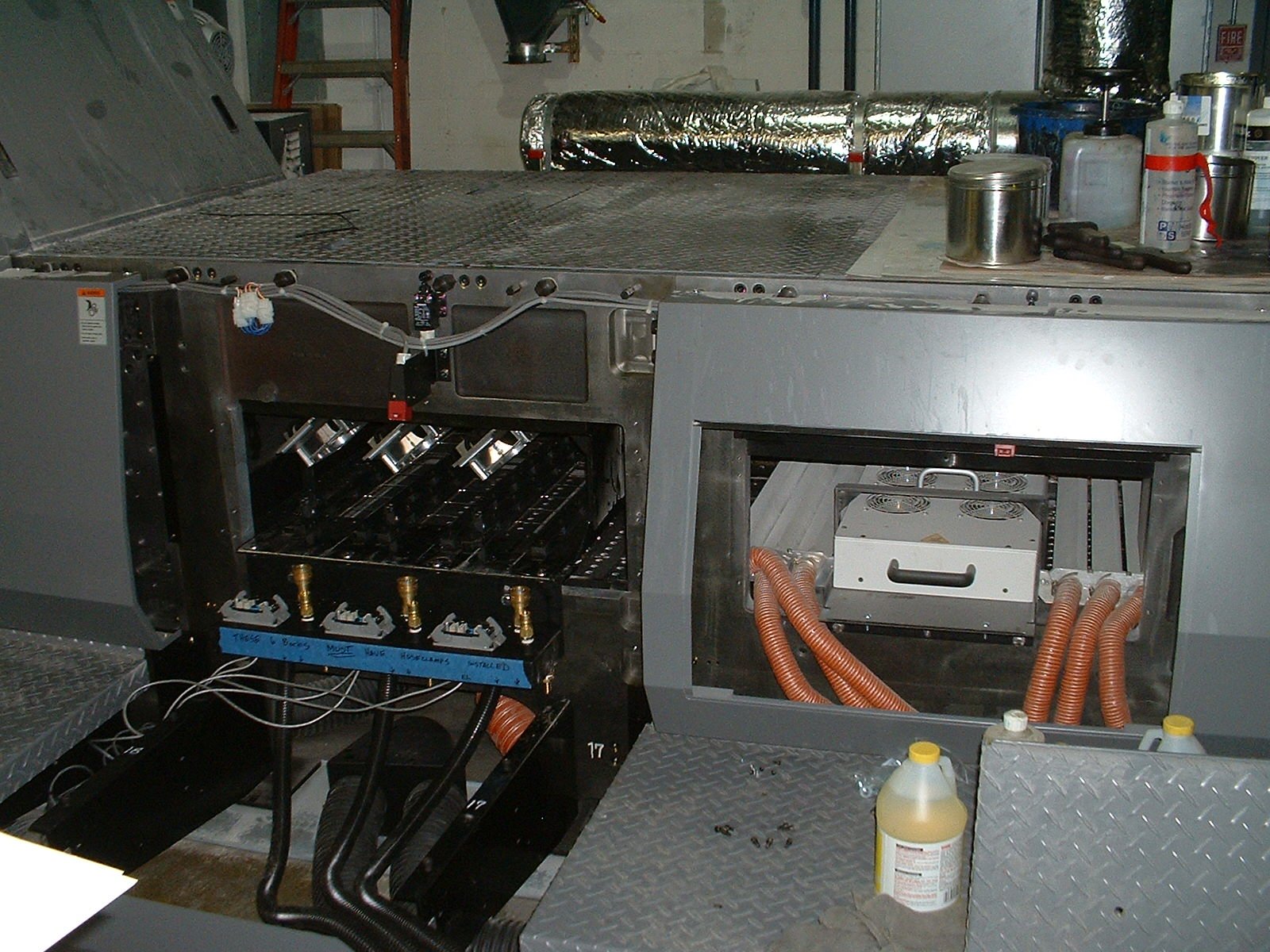

Prime’s IR ACTION CASSETTE

Prime’s IR Emitters are manufactured using the finest quartz available to ensure durability, reliability and longevity. Prime’s IR Cassette design allows the use of either Prime’s Short Wave, Fast Medium Wave or Medium Wave IR Emitters. Providing these options enables the IR Cassette to emit IR Energy best matched to the absorption spectrum of both chemistries and substrates used to optimize drying efficiencies. Providing maintenance ease, Prime’s IR Cassette simply slides in & out to allow fast and easy access for any servicing.

The IR Emitter Zone allows adjustments of the IR Cassette’s distance to the substrate to best accommodate material thickness variations. All of Prime’s IR Emitter’s come with Gold Reflectors which reflect more than 90% of IR output to the substrate. Further reducing energy consumption, Prime’s IR cassettes are powered by Prime’s PREMIER Controls. Controls that enable IR section activation to best match substrate width variations and automatic 1% power output changes to best match process speed

Prime’s IR Zone ensures the highest radiation efficiency with minimum convection loss. The IR Zone includes a series of fans directing heat towards the substrate. This IR Zone delivers maximum radiation power in minimal space.

-

All of Prime’s IR-AK Dryer Series Chamber include dual HAK3 zones to maximize acceleration of drying process. Each HAK3 zone consists of three Heated Air Knifes to match substrate widths. Prime’s innovative HAK’s geometry guarantees constant hot air stream to expedite drying process and maximize drying speed. Prime’s design combines convection, IR Radiation and air-impingement drying technologies creating a superior, more energy efficient dryer.

-

Prime’s visionary PREMIER control technology safeguards your production process via Prime’s PREMIER 7” Color HMI, which can be located at press control console. Continuously monitoring and logging critical IR system data, Prime’s PREMIER controller automatically alerts users if adverse operating conditions arise. A wealth of information available anywhere via a simple ethernet connection. Prime’s PREMIER controller delivers a preemptive strike against any unplanned downtime and ensures Prime’s IR ACTION operates at peak efficiency.

-

Prime’s IR ACTION Dryers match automated controls with most current electrical devices to optimize IR ACTION Dryer’s performance and ensure ease of installation and service. Output power controlled via analog signals or fieldbus connections. Soft start control feature gradually raises current until emitter reaches steady state. Emitter connections protected with small, easily manageable power cross-sections. Highest quality solid state relays provide 1% variable power output.

-

Enable IR section activation to best match substrate width variations

Include automatic 1% power output changes to automatically adjust to best match process speed and substrate temperature.

Maximize IR Emitter life

VFD control of HAK – high-pressure air impingement technology to increase energy efficiency and optimize drying performance to best match ink coverage, substrate type and press speed.

Get in Touch with a Product and Application Specialist

Contact us to learn how Prime UV-IR’s curing and drying solutions can improve your production process, reduce your energy consumption and expand your product offerings.