Ultra-Violet (Energy Curable) Curable Pressure Sensitive Adhesives

With so many advancements made in Energy Curable PSA’s in recent years, converters should all be seriously evaluating whether to adapt this very energy efficient and affordable technology into their converting process. UV PSA’s provide enormous benefits over 3 other PSA Technologies which include solvent-borne (create VOC’s – Volatile Organic Compounds), hot melt (low solvent resistance) and water-borne (large space requirement to dry.)

UV PSA advantages include but are not limited to the following:

100% Solids - Eliminate the need for solvent extraction or solvent storage.

Explosion-proof equipment and ovens with drying zones are not required

Lower operating cost, improved ROI

High productivity & good processing flexibility

Efficient thick film production - NO preheating necessary.

Able to use on wide variety of substrates, including heat sensitive substrates.

PVC, elastomers and polyethylene and many more.

Immediate cure.

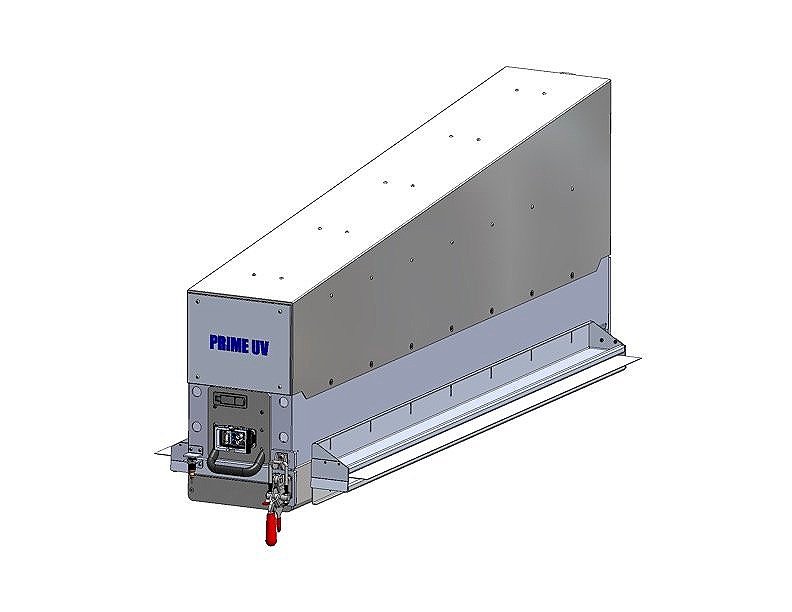

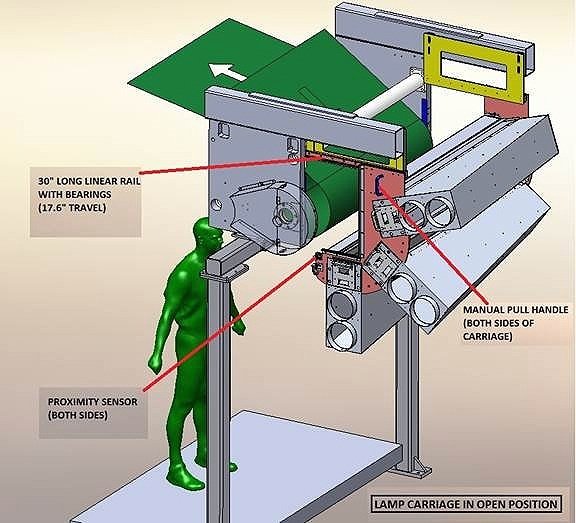

Tremendous space savings – easy to install and to retrofit in-line.

Enormous energy savings.

High-performance characteristics such as temperature, tack, shear resistance and peel strength.

improved dimension accuracy

higher heat resistance

better chemical resistance

if required, easy to apply heavy coating weights

Viscosity easy to adjust to accommodate the use in any deposition method.

Other UV Curing Advantages:

crosslinked systems with a balance of adhesion and cohesion.

no residual monomers or solvents.

no oxygen inhibition required.

Today UV PSA’s are formulated to use in a wide variety of applications which include:

removable, semi-permanent and permanent applications.

Labels and tapes

Performance graphics and vinyl applications

High deposition (coating weight) specialty markets

Laminating adhesives

Assembly of medical, LCD, electronic components, automotive and others.

Ultra-Violet (Energy Curable) Pressure Sensitive Adhesives Formulators / Manufacturers:

Henkel Adhesives: www.henkel-adhesives.com

Recommended prime products for this application

Get in Touch with a Product and Application Specialist

Contact us to learn how Prime UV-IR’s curing and drying solutions can improve your production process, reduce your energy consumption and expand your product offerings.