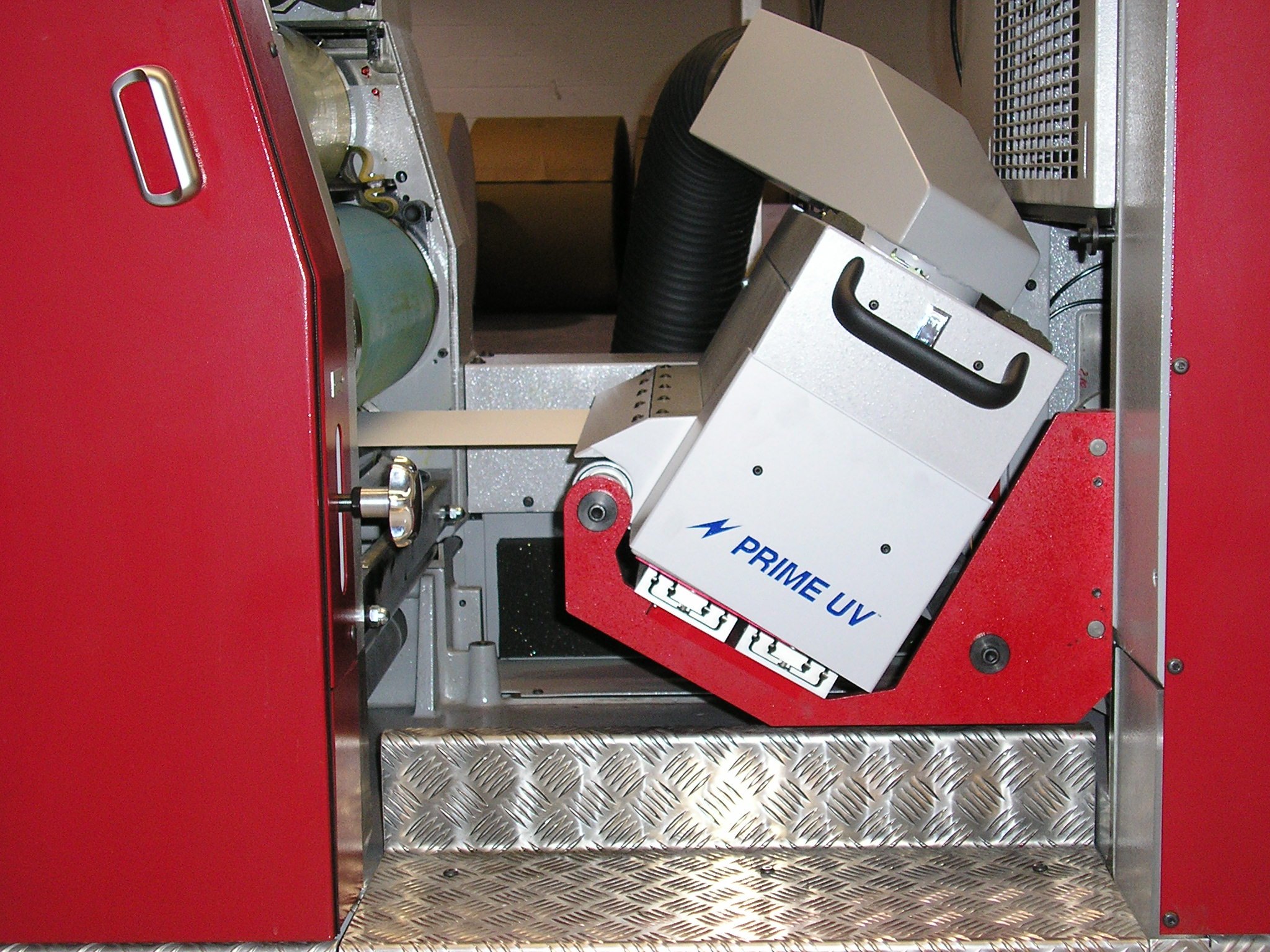

cold foil and hot stamping Applications

Cold Foil technology allows Printers and Converters the ability to apply eye-catching foils in-line. A standard printing plate is used to apply UV curable adhesive. The cold foil is laminated using a nip and the remainder of the unused foil web is peeled away by rewound.

Printers and Converters gain the benefits of

Less expense

Achieve higher speeds

Produce Holograms

Quick turn-around

Get in Touch with a Product and Application Specialist

Contact us to learn how Prime UV-IR’s curing and drying solutions can improve your production process, reduce your energy consumption and expand your product offerings.