UV Coil Coating Business Applications

UV Coil coating is a continuous and highly automated industrial process to efficiently UV coat coils of metals. Because the metal is treated before it is cut and formed, the entire surface is cleaned and treated, providing tightly bonded finishes. UV Coil-coated metal is often considered more durable and more corrosion-resistant than most painted materials.

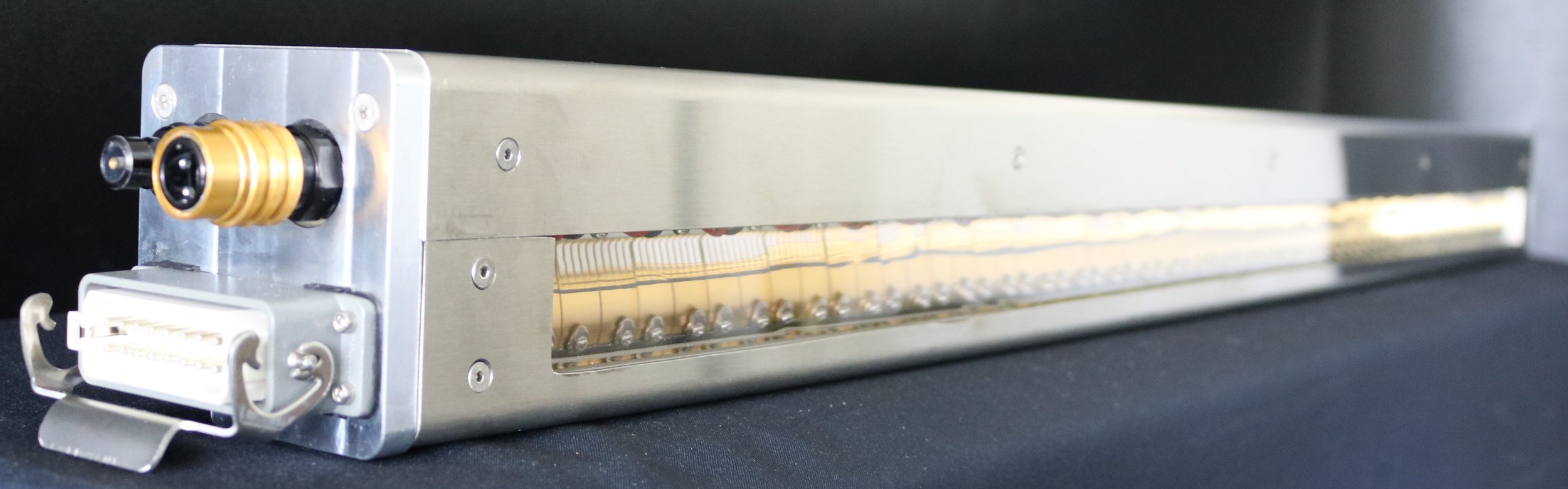

Today advances in UV Coil Coating formulations are leading to the dramatic decarbonization of the global coil coating market. These advances in UV Chemistry are leading coil coating companies to either retrofit or replace existing conventional coil coating lines with UV Curing Systems. UV systems require a much smaller equipment footprint than conventional thermal dryers. UV formulations provide a more durable product with an additional protective layer that is more corrosion-resistant. In addition, these UV formulations are 100% solvent free thus eliminating the need for using incineration equipment to capture and partially destroy VOCs created.

Coil coating is used in a wide variety of applications including: aluminum closures, easy open ends, valve caps, pharma caps, menu trays, cosmetics and perfumery packaging, construction materials such as metal roofing, facades and panels.

There are many additional industrial applications that utilize UV curing, such as:

Industrial Adhesives

Cable & Pipe

Plastics

Recommended prime products for this application

Get in Touch with a Product and Application Specialist

Contact us to learn how Prime UV-IR’s curing and drying solutions can improve your production process, reduce your energy consumption and expand your product offerings.